Menu

Edit

ADDRESS

Pidilite Industries Ltd,

Ramkrishna Mandir Road,

P.O. Box No. 17411,

Andheri (East) Mumbai – 400059

Check out the biggest trends of the season and our expert take on them.

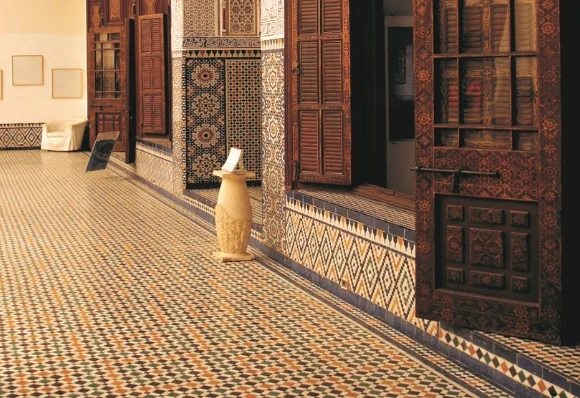

If you’re planning to get new tiles for your home, you may want to check out the diverse range of vitrified tiles available on the market. These tiles have become a preferred choice among homeowners, contractors, and builders. Different types of vitrified tiles are used across walls, floors, and specialized applications thanks to their durability, cost-effectiveness, and designs. If you want to know all about vitrified tiles, we have covered important details about the same that will broaden your understanding of these construction materials. Let us take a glance at them:

Vitrified tiles are similar to ceramic tiles in many aspects. However, they also contain silica and clay that melt and merge during the vitrification process to produce a glass-like element within each tile. This allows vitrified tiles to keep their original gloss for years to come imparting a great finish to its surface. These tiles are available in a wide range of shapes, designs, and colours, making them an attractive alternative to natural stones like marble or granite. However, you need to keep in mind that vitrified is surely an investment as it is slightly more expensive than other options because of the presence of silica and clay, as well as the vitrification treatment. This production process makes it highly non-porous at less than 0.1% of water absorption which makes the traditional cement usage

for tile fixing redundant.

Before choosing the best vitrified tiles for flooring, it is important to learn about their types. Different manufacturing techniques and procedures define different qualities and types of vitrified tiles. Broadly, there are three types of vitrified tiles:

Glazed vitrified tiles have a glazed surface and are produced using digital technology to achieve a variety of patterns and appearances on the tile. Some of the popular designs include wood, bamboo, marble, and so forth that are precisely replicated to give a realistic look. Since the glaze layer imprinted on these tiles is generally less than 1 millimeter thick, they are only suited for places with low or moderate traffic.

The colour of full body vitrified tiles is consistent throughout their thickness. This is because the pigment combination is added right at the start of the production process to achieve a homogenous colour that is uniform all through the tiles. As a result, these tiles will never discolour or fade in their lifespan. Owing to this feature, full-body vitrified tiles are best suited for areas that have high traffic because scratches are barely noticeable. For their performance, these tiles are the most expensive of the lot.

On the surface, glazed and full-body vitrified tiles may appear identical; therefore, it is imperative to review the technical parameters of these vitrified tiles before purchasing them for your home.

During the manufacturing process of double charged vitrified tiles, two different tones of pigments are used. On these tiles, the press imprints a 3–4 mm thick layer of a dual-coloured design. The best thing about double charged vitrified tiles is that they are extremely durable, require minimal to no care, and are appropriate for high-traffic areas.

Here are some parameters for choosing the best vitrified tiles for flooring:

Vitrified tiles are ideal for use in bathrooms, room flooring, or backsplash in the kitchen. The vitrification process hardens and weatherproofs the tiles, allowing them to be used in both indoor and outdoor areas. Besides, these tiles can also be installed on the roof or in the garden because they of their high-pressure endurance.

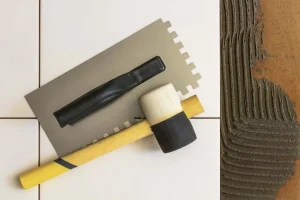

Vitrified tiles have less than 0.1% porosity and hence will not be able to bond well with the traditional cement-based application. Traditional application will lead to de-bonding of tiles and lippage due to non-establishment of bonding between the tiles and the substrate. To avoid this, it is recommended to use tile adhesives which have added polymer content to facilitate the bonding between the two surfaces. It helps avoid the aforementioned disadvantages. Roff recommends tile adhesives based on the needs and substrates and adhere to the Indian and European standards. One can visit here to choose the right adhesive.

The intrinsic qualities of vitrified tiles make them resistant to stains. As a result, these tiles are very simple to clean and maintain, requiring only water and basic cleaning solutions. For removing more persistent stains from vitrified floor tiles, one can try Roff Cera Clean. Besides, the grout between the tiles have to be carefully chosen to ensure maximum life and of the tile joints and increase the aesthetics of the room. For tile joint fillers, explore the product range of cement or epoxy based grout fillers by Roff, India’s leading company offering advanced tile and stone fixing solutions.

For any queries or assistance, get in touch with us at 1800 2255 02 or mail us at info@roff.in. Our customer support team will reach out to you and arrange a site visit if required.